|

|

|

|

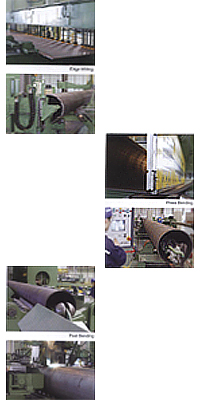

High quality plates are produced from well-known

local manufactures, or are imported from leadinmg steel

mills abraod. Thereafter, physical and chemical properties

are checked in the laboratory and verified with the test

certificates. Tese plates are accuratelycut to the required

dimention, edges are prepared as per manufacturing codes,

and then fed into the rolling machine

The plates are rolled in the rolling machine into cylindrical

shape of lengths varying from 4 – 12 mtrs.After

post pinch operation, the pipes are subjected to tack

welding. Thereafter the longitudinal seam is submerged

arc welded both from outside and inside, to form a strong

weld joint. During the process of welding, and thereafter,

strict inspection is enforced

The pipes are then moved to the gauging press to achieve

perfect roundness. The pipes-ends are believed whenever

required by the customer. Each pipe is subjected to strict

quality control. The pipes undergo on-line multi-channel

ultrasonic testing apart from radiography and hydrostatic

testing as per the relevant codes and specifications to

which SAW pipes are manufactured. All the three Units

of the Group have well-established testing arrangements

both for non-destructive and destructive tests. They are

well-equipped with facilites for chemical analysis, as

well as tensile, hardness and bend testing. Each pipe

bears Sr.no., Test pressure, Specification Code, Size,

O.D.,Wt, and Length. Finally Mill test Certficate is issued

for each pipe. API stamp is embossed on pipes manufactured

conforming to API Specifications.

|

|

| |

|